-

R&D Capability

We have an experienced professional technical team. After years of R&D innovation and technological accumulation, we have formed multiple core technologies in product and mold development, product manufacturing processes, automated production line design and experimental testing.

Process Capability

Manufacturing Capability

-

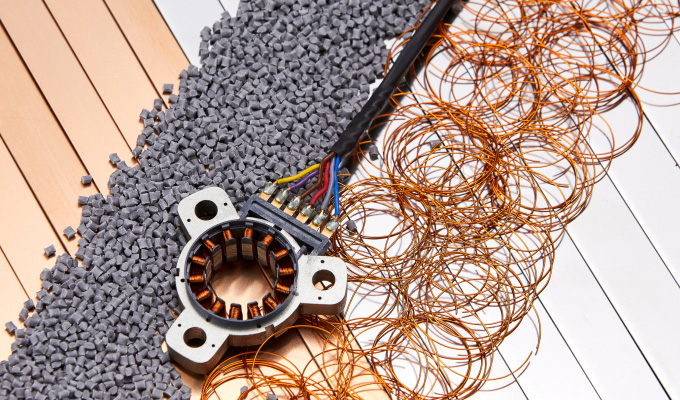

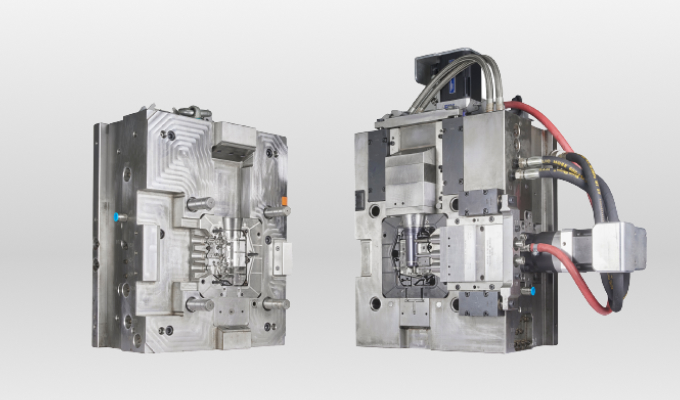

Mold

MoldMold is the mother of industry. We have possessed multiple core technologies in mold design and manufacturing. Through the development of intelligent manufacturing systems and UG controls, we have achieved 3D coloring and process color management for various procedures, so that the process routes and processing requirements can be more clearly and accurately transmitted to the site and the entire process can be visualized and managed. It consists of precision injection mold and precision stamping mold.

We are good at machining difficult parts and can realize the maximum machining accuracy as high as ±0.001mm on the grinding machine; CNC machining accuracy as high as 0.003mm; the highest precision of 0.002mm in wire cutting machining planes; and the precision as high as 0.002mm in electrical discharge machining.

-

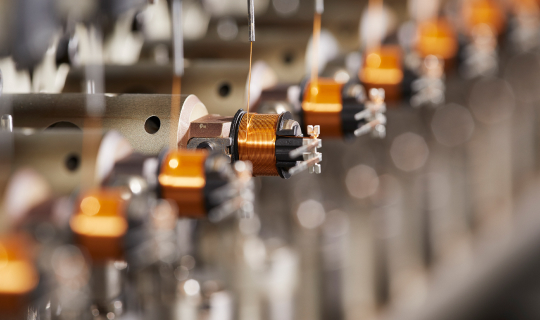

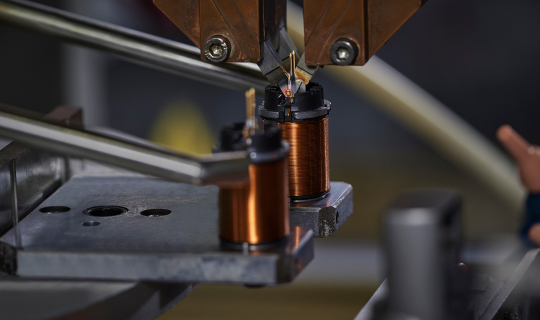

Automation

AutomationWe have a group of excellent R&D, design, manufacturing and assembly professionals who can effectively integrate multiple processes and automation technologies to achieve high efficiency, high quality, low cost, fully automated and flexible production.

Independent R&D is based on the industrial IoT data traceability system to achieve the traceability function of product quality. We can maturely use modular automation production line development technology to achieve rapid transformation and program switching of production lines or equipment through mechanisms and technology application for producing multiple products.

Experimental Capability

Equipped with advanced testing and experimental equipment at home and abroad, the company can provide CMM testing, cleanliness testing, mechanical testing, electrical performance testing, climatic and environmental testing, corrosion resistance testing (salt spray testing), metallographic testing, fluorescent film thickness testing, XRAY testing, GOM scanning, etc. and is able to provide complete, fast and reliable performance testing of automotive electronic products, to effectively improve the technological R&D capabilities and quality control capabilities of the company.

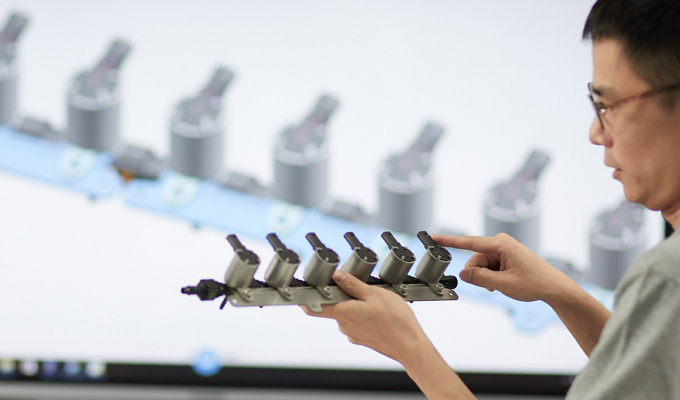

One-stop Solution

The company can meet the full process requirements of product R&D, preliminary synchronous engineering, product process development, digital mold development, highly automated production, reliable quality control and reliability verification and provide customers with a one-stop integrated solution.

Throughout the entire service process, multiple departments, such as sales, R&D, process, quality, production and supply chain, collaborate to keep continuous improving and optimizing so as to ensure product delivery, quality and high cost-effectiveness.